e2ip technologies acquires True North Plastics Inc. – Learn more

Integration

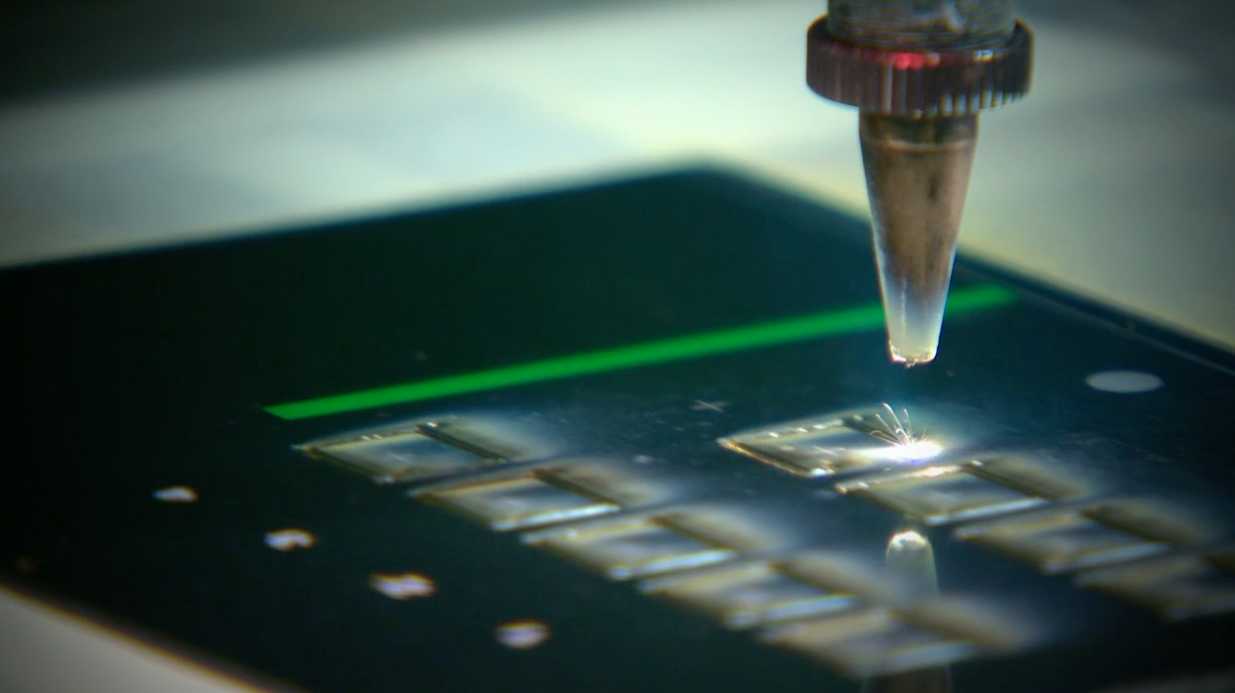

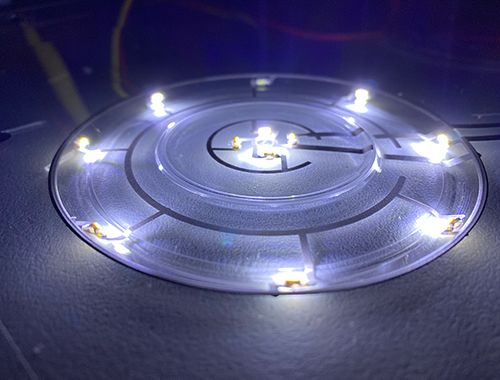

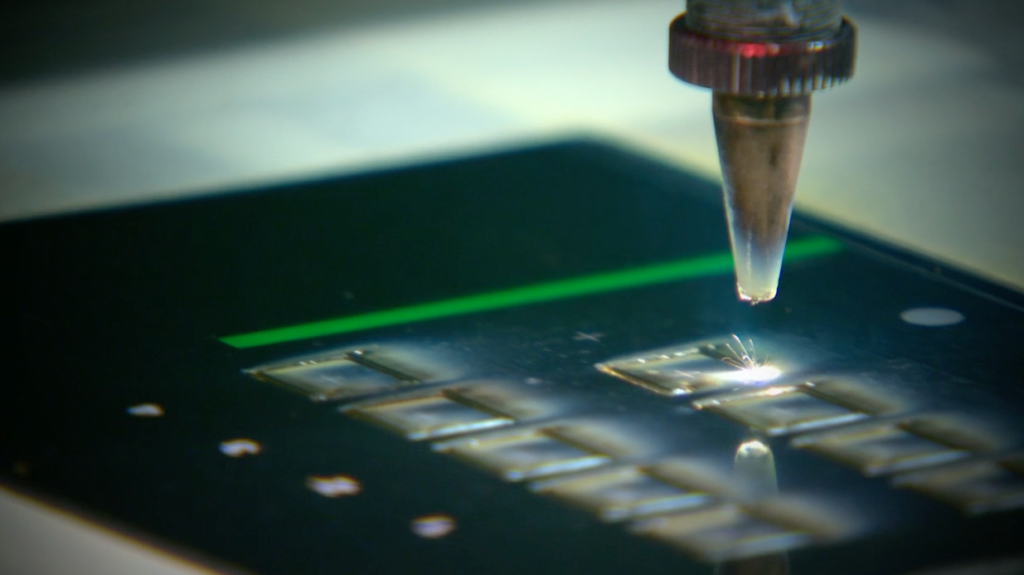

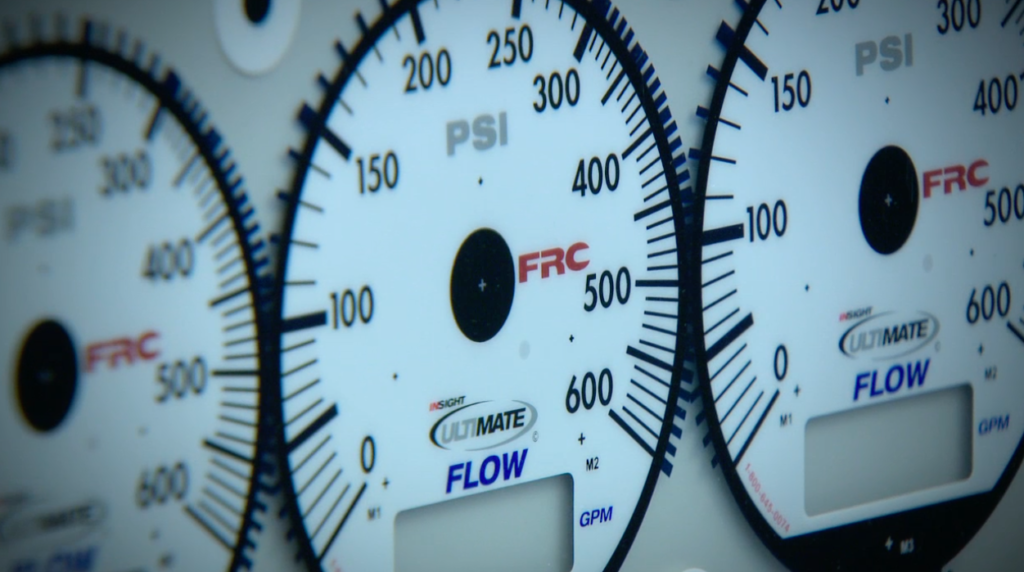

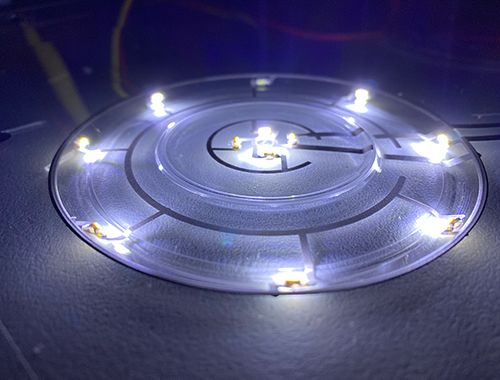

We take a product from concept to reality. Starting with 3D design in Solidworks, graphic design, screen or digital printing, high pressure forming (in mold decoration), laser trimming, pick and place assembly, and testing.

Quality

Quality drives True North manufacturing; all of our products are built under our detailed quality system. Our in house developer manufacturing and quality control software integrates with our customers through a web portal.

Innovation

From conceptual thinking through design and manufacturing. We take pride in our products from start to finish!

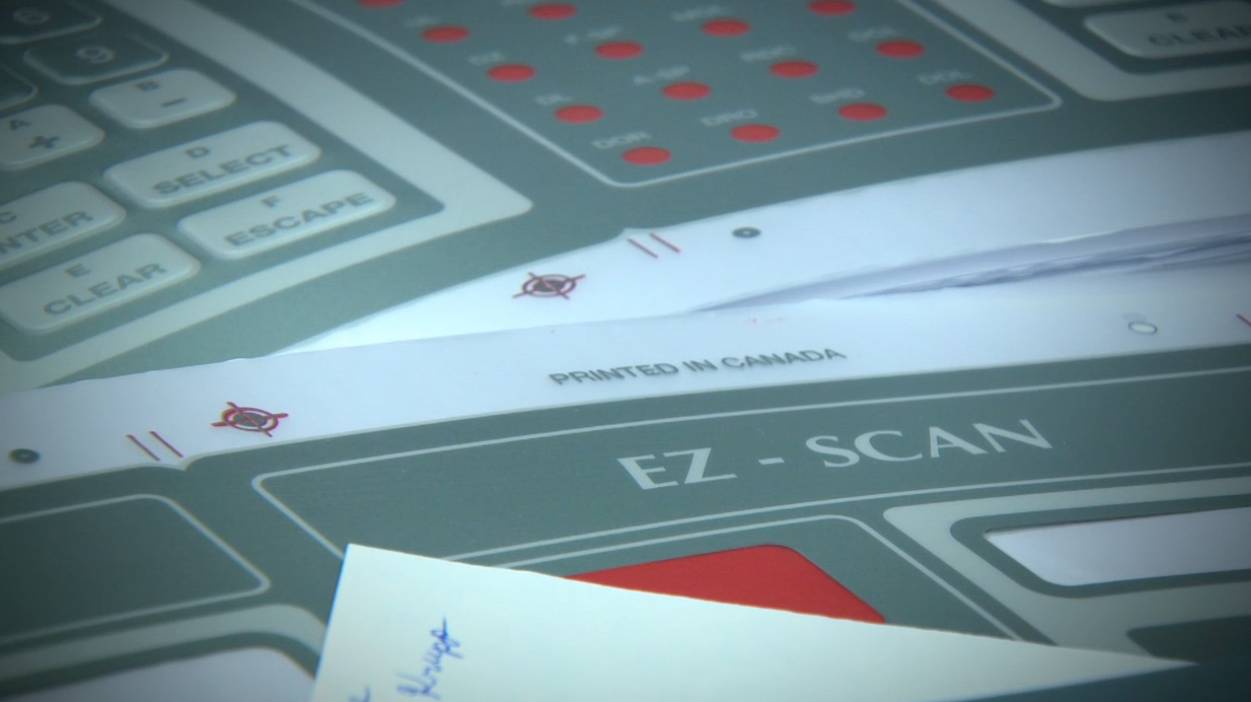

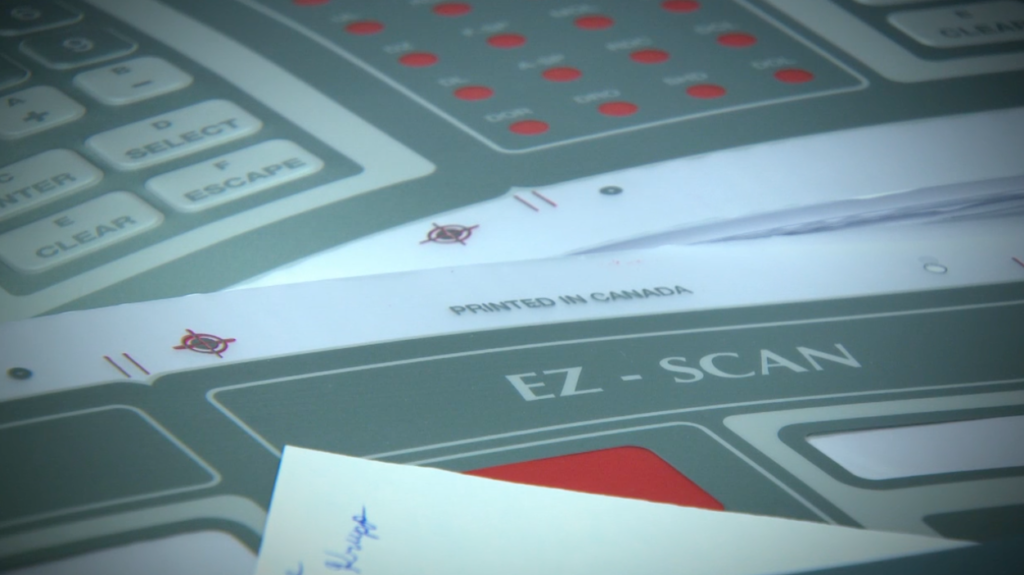

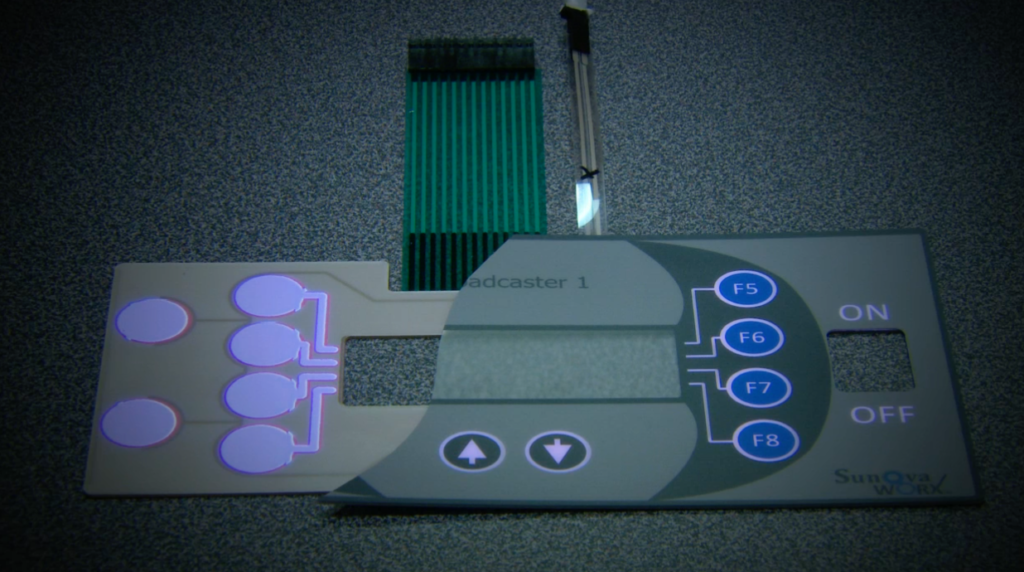

Whether you need a label, a membrane switch, or a formed product including functional electronics and graphics, we put the same care into everything we make.

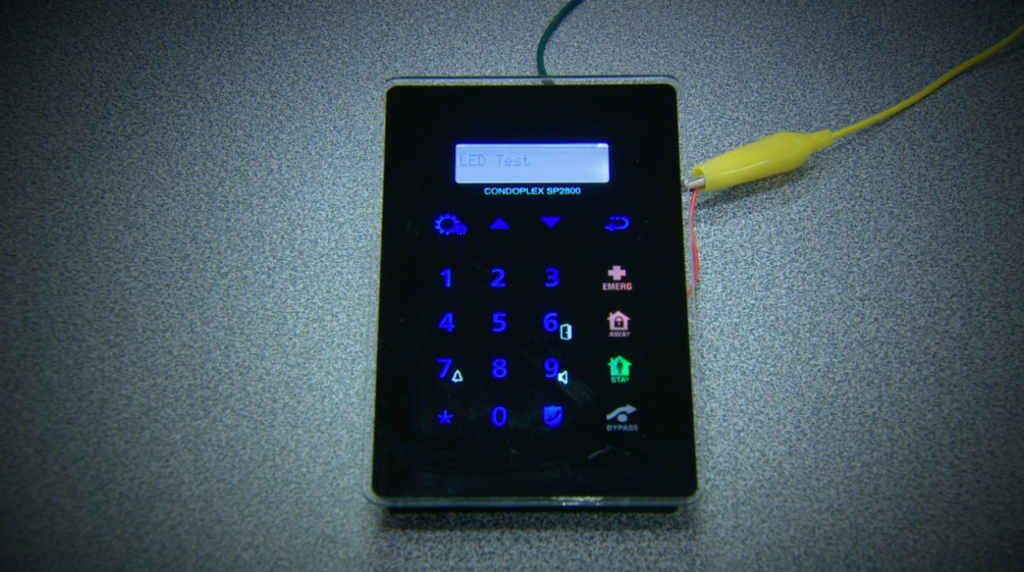

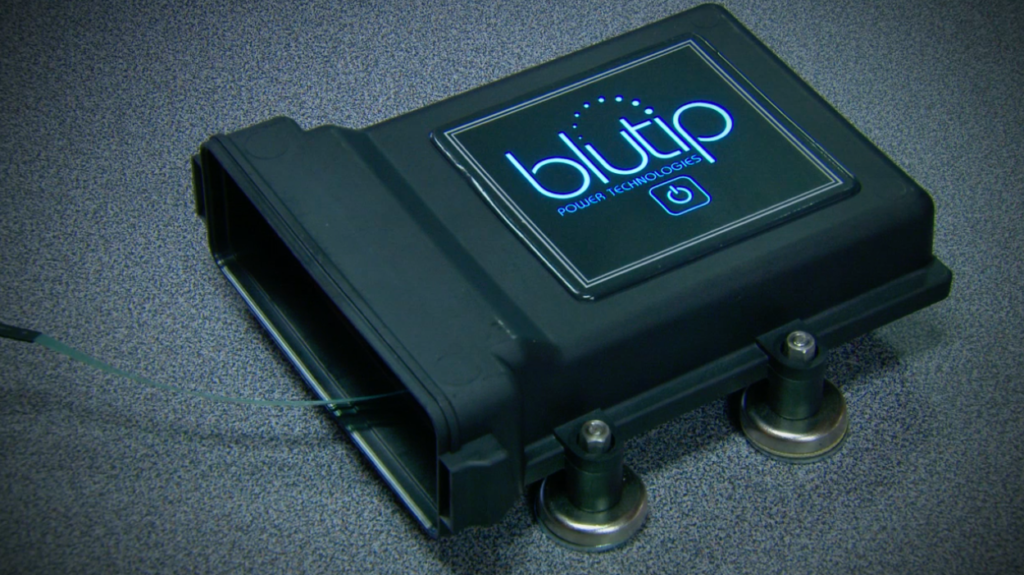

Since 1985, True North Printed Plastics has been building highly specialized interfaces between users and products. Our team creates “The Human Interface”. Capacitive touch to membrane switches, thin film forming, formed electronics, in mold decoration, graphic overlays and labelling projects; The True North team has experience in all forms of connectivity. Whether a customer idea arrives on a cocktail napkin or a full set of CAD drawings, True North Printed Plastics develops and builds these products to meet your needs. We look forward to your challenges and aim to exceed your standards. We specialize in those projects that require extra thought and imagination. Bring us your dreams.

We offer a wide range of options from digital printing on our 3 Roland LEF-300 digital presses, through to screen printing on our conventional or UV lines. We can form complex geometries into your product to add functionality and beauty. At True North Printed Plastics we are happy to tackle projects from 1 prototype membrane switch, to production runs in the tens of thousands. We are your resource for printed plastics.

Contact us for more information:

customerservice@truenorthpp.com